At HomeQuestionsAnswered, we're committed to delivering accurate, trustworthy information. Our expert-authored content is rigorously fact-checked and sourced from credible authorities. Discover how we uphold the highest standards in providing you with reliable knowledge.

What is an Induction Furnace?

An induction furnace is an electrically run furnace used for melting metals. It produces heat by the use of an alternating current solenoid coil, otherwise known as electromagnetic induction. They are most often found in the scrap metal industry.

The induction furnace was first invented in 1877 in Italy. The first use of the furnace was in 1927 in Britain. It wasn't until World War II, when the need for aluminum casting grew significantly, that the induction furnace went into wider usage.

Electromagnetic induction is the process that allows an induction furnace to work. It was first discovered in 1831 by Michael Faraday. During induction, an electric current is passed through a metal coil which creates a magnetic field. When metal is introduced into the magnetic field, an electrical current passes through the metal and causes it to heat. The most common household use of this process is in a rice maker. The pot that contains the rice is placed on top of a metal coil and is in turn heated.

There are two types of induction furnaces. The first is coreless and the second is called channel. Both are in use in the early 21st century.

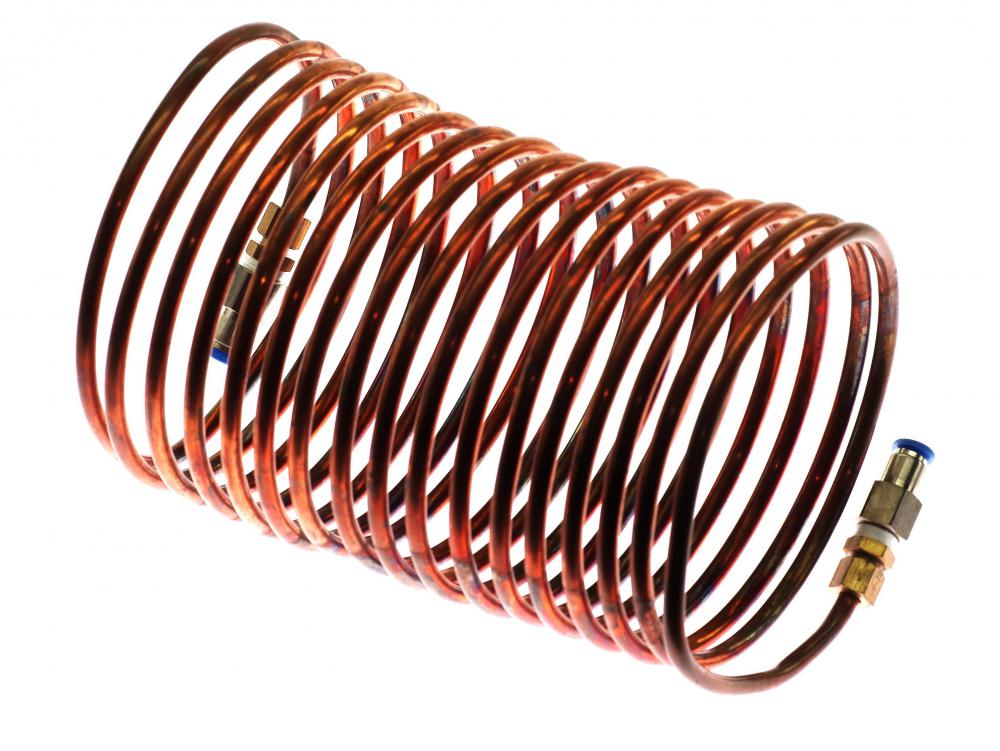

The coreless induction furnace has copper coils that are protected by a steel and magnetic shield and kept cool by water circulating from a special cooling tower. A layer of refractory, or difficult to melt material, is placed above the coils and heated to the desired temperature. A crucible, which is a melting pot made of heat resistant material, is above the refractory. The metal to be melted is placed inside the crucible and the heat produced by the electromagnetic charge melts the scrap.

The channel induction furnace can also be called a core induction furnace. It functions very similarly to the coreless furnace, except for the addition of a heated core. Channel furnaces were originally used as molten metal holders, but have been found useful in the melting of lower melt temperature metals.

Both types of induction furnaces produce a natural stirring motion when the metal is molten. The pull of the magnetic fields and electrical currents cause the materials to sway in different directions. This stirring is essential to maintaining the integrity of the metal. The coreless furnace creates a more violent stirring, while the channel is known to have less turbulence at the surface.

After melting, the molten metal is poured into a mold. Some pouring methods are fully operated by human hands. Others are mechanical with human intervention, while others are fully automated. Mechanical systems are more efficient for large scale projects, while manual pouring methods are more suited to low volume production lines.

AS FEATURED ON:

AS FEATURED ON:

Discussion Comments

There is no description of its construction and its chemistry which i want for my studies.

I had a friend who used one of these in a metal casting class she took in college. The concept of working with a melting furnace every day terrifies me, but I guess if you want to do metal working it's something you have to get used to.

There is no description of its construction and its chemistry which i want for my studies.

Post your comments